SPK, SPL sanitation containers for saws

SPK and SPL are sanitation containers for saws with electric heating designed for slaughterhouses and meat processing operations. Sanitation occurs when saws are dipped into the container with hot water.

The water temperature of 83°C in the container is kept up by means of an electronic temperature regulator with a digital display. If the container is switched on with no water in it or if water is leaking during the operation, the electronic temperature regulator switches off the unit thus prevents damage of the heating body. The sanitation container is equipped with plastic guided plate to prevent the edges of the saws from being taken off, with inlet and outlet valves and spillover to ensure a maximum height of the water level. A low temperature of the container’s surface is ensured by its double casing and a plastic covering plate. The water inlet is equipped with backflow valve.

Sanitation containers are intended for a quality and safe sanitation of saws used at slaughterhouses and meat processing operations.

Package contents

- container with sheathing

- covering plastic plate

- heating bodies as per total power requirement (800 W per a heating body)

- electronic thermostat

- inlet and outlet valve

- plastic guided pad

| Water inlet | G 1/2“ |

| Water pressure | 0,1 – 1 MPa |

| Electricity protection | IP 55 |

| Power supply | 230 V, 50 Hz (400 V SPK 02) |

| Temperature of sanitation liquid | 83°C |

| SPK 01 | |

| Power requirement | 1600 W |

| Outlet | G 3/4” |

| Capacity of container | 10 l |

| Weight | 31 kg |

| SPK 02 | |

| Power requirement | 4800W |

| Outlet | G 1” |

| Capacity of container | 50 l |

| Weight | 47 kg |

| SPL 01 | |

| Power requirement | 2400W |

| Outlet | G 3/4” |

| Capacity of container | 8 l |

| Weight | 32 kg |

| SPL 02 | |

| Power requirement | 3200W |

| Outlet | G 1” |

| Capacity of container | 15 l |

| Weight | 38 kg |

- Set up water inlet G 1/2”

- Set up outlet as per type of container

- Set up power supply in accordance with the voltage and power requirement of the sanitation container, which must be connected via a switcher corresponding to particular surroundings.

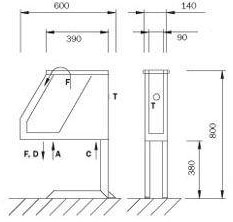

SPL 01

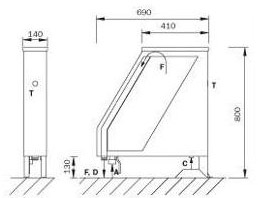

SPL 02

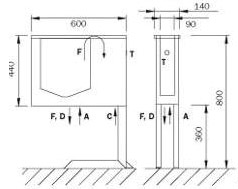

SPK 01

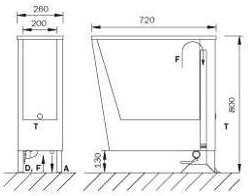

SPK 02

- A –

water inlet

- C –

electricity supply

- D –

outlet

- F –

spillway

- T –

temperature indicator

n

n

n

n